Conveyor Safety

Conveyors are used to move materials and supplies in and out of a work site, from one part of the plant to another, and between workstations. Conveyors can be powered or use gravity or momentum to transport objects. Gravity conveyors include those that have rollers, wheels or chutes. Conveyors are convenient and beneficial for quickly moving materials, but operating an unguarded conveyor can lead to serious injuries and death.

Remember! Working at a conveyor or belt may include manual material handling, including repetitive motions, reaching, and lifting that may lead to musculoskeletal injuries, especially when movements are done quickly and for a long period of time.

Conveyors must be designed and installed with attention to worker safety, as well as productivity. Common hazards around conveyors include:

- Shear points

- Pinch points

- Spills and falling materials

- Power transmission interfaces, such as drives or shafts

Employers

Employers are responsible for ensuring that conveyors and machinery are safe, and that all applicable regulations are followed. Employers must identify job-related hazards. Once the hazards are identified, the employer must implement safe work procedures, with input from the joint health and safety committee (JHSC), or health and safety representative. If the workplace does not have a JHSC or health and safety representative, the employer should work directly with the affected employees and supervisors to identify hazards and safeguarding solutions. Employers are responsible to train their employees on the safe use, maintenance and repair of conveyors and the safety devices.

Specifically, employers must ensure that:

- There is enough clearance between the material being transported and any fixed or moving object.

- Shearing points between the moving and fixed parts are avoided.

- Material is not fed onto a stopped conveyor.

- Power-driven conveyors that can be accessed by employees have emergency stop devices at the loading and unloading stations, drive and take-up sections and other accessible places along the run of the conveyor.

- The conveyor has an anti-rollback device for loads carried up an incline.

- An elevated conveyor that an employee can access must have a walkway along its entire length that is not less than 500 mm wide and is equipped with guardrails.

- Designated crossing areas are provided where employees must travel over a conveyor.

- Sheet metal or screen guards are installed under or alongside the conveyor, if it is not entirely enclosed, to prevent material from falling off the conveyor.

- A conveyor that is accessible by employees has adequate safeguards that extend 1 m from the pulleys and along the sides of a belt conveyor.

Where conveyor belts are used underground:

- The conveyor belt must be made of fire-resistant material, or

- An automatic fire extinguishing system must be installed.

While the employer is ultimately responsible for all the provisions mentioned above, the supervisor has a vital role to play in the safety of their teams. As a supervisor, you must:

- Acquaint your employees with the hazards and control measures associated with their work

- Provide the information and instruction necessary to ensure their health and safety

- Enforce company safety rules, programs, codes of practice and procedures, including ensuring employees comply with the requirements below.

Employees

Employees must:

- Never climb or stand on a conveyor frame to load, unload or clear a blockage, unless it is stopped and locked out .

- Never remove heavy or bulky articles by hand from a moving conveyor unless at a designated station.

- Never ride or sit on a conveyor.

- Not do maintenance or complete repairs on a conveyor without following lock-out procedures.

- Wear close-fitting clothing and ensure head and facial hair is cut or confined when working near a machine where clothing may come into contact with moving parts.

Additional requirements when working with other types of conveyors

Spiral Chute Conveyors

When maintaining fire separations between parts of a building, spiral chute conveyors must:

- Be built into a fire-resistant shaft with doors at each end.

- Have automatic fire doors or draft checks when the chute of the conveyor passes through different parts of the building.

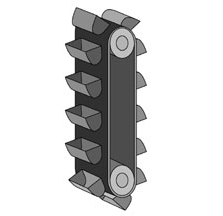

Bucket Conveyors

Inclined vertical and horizontal bucket conveyors must have a safeguard that:

- Fully encloses the conveyor.

- Is made of a solid material.

- Has at least one wire glass window measuring at least 2.1 m in height, extending to the full height of the conveyor.

Power Driven Conveyors

"Powered" or "power" conveyors include the use of belts, live rollers, slats, or buckets. Locate the emergency stop cut-off switches for power driven conveyors and ensure they are accessible to employees at:

- Loading and unloading stations.

- Drive and take-up sections.

- Other convenient places along the run of the conveyor.

Screw Conveyors

Screw conveyors are troughs with a revolving shaft with a spiral or twisted plate. The revolving mechanism and any connections to the power source should be enclosed, except for the loading and unloading points. Screw conveyors must:

- Be in metal troughs.

- Have covers that are made of metal or another equally protective material.

- Have secured covers at least 3 mm thick.

- Be covered in sections with removable plates.

When a screw conveyor is fed from the floor level, adequate safeguards must be provided around the opening.

Pneumatic Conveyors

Protect the opening of all hand-fed pneumatic conveyors that are at least 300 mm wide to prevent employees from being pulled into the conveyor.

Pneumatic conveyor fans must be:

- Guarded and all intake openings protected by metal grating or metal screens made of fire- resistant material.

- Secured to a support or foundation able to tolerate the load.

- Positioned so employees have easy access and can safely do maintenance or repairs.

- Able to be remotely controlled, in addition to the normal operating controls.

If flammable materials will pass through a pneumatic conveyor's fan, it must be made intrinsically safe by:

- Installing fan blades and spiders made of non-ferrous material.

- Ensuring the fan’s casing is lined with non-ferrous material.

When working with an enclosed or pneumatic conveyor carrying explosive or flammable material:

- Install an adequate explosion prevention system or safety relief vents leading as directly as possible to the outside air.

- Ensure vents are not connected to chimney pipes, vents or flues used for other purposes.

- Install counter-balanced relief valves on the safety relief vent outlets for protection when it is essential that materials not be able to fall or escape from the enclosed conveyor.

General Regulation - Occupational Health and Safety Act

N.B. Reg. 91-191

Part XVI MECHANICAL SAFETY

Section 241 Contact with Machines

241. (1) An employer shall ensure that sufficient space is provided around a machine in order to ensure the safety of employees while the machine is being operated or while cleaning, maintenance, adjustments or repairs to the machine are being carried out.

(2) Where an employee or the employee's clothing may come into contact with moving parts of a machine or a moving machine, the employee shall

(a) wear close fitting clothing,

(b) confine or cut head and facial hair, and

(c) not wear jewellery, rings, dangling neckwear or similar items.

Section 255 Conveyors

255. (1) An employer shall ensure that a conveyor is constructed and installed so that

(a) sufficient clearance is provided between the material transported and any fixed or moving object,

(b) shearing points between moving and stationary parts are avoided, and

(c) the conveyor is not able to feed onto a stopped conveyor.

(2) An employer shall ensure that a power driven conveyor to which an employee has access is provided with emergency stop devices at

(a) loading and unloading stations,

(b) drive and take up sections, and

(c) other convenient places along the run of the conveyor.

Section 256

256. (1) An employer shall ensure that a conveyor installed underground or in any other place where a belt fire of the conveyor may endanger the life of an employee is

(a) made of fire resistive material, or

(b) protected by an adequate automatic fire extinguishing system.

(2) Where it is necessary to maintain a fire separation between parts of a building, an employer shall ensure that a spiral chute conveyor is

(a) enclosed in a shaft made of fire resistive material with doors at each end of the shaft, or

(b) provided with automatic fire doors or draft checks when the chute of the conveyor passes through the parts of the building.

Section 257

257. An employer shall ensure that a conveyor that carries a load up an incline is equipped with an anti-rollback device.

Section 258

258. (1) Where employee access to an elevated conveyor is necessary, an employer shall ensure that the elevated conveyor has a walkway along its entire length that is not less than 500 mm wide and is equipped with guardrails.

(2) Where an employee is required to cross over a conveyor, an employer shall ensure that adequate crossing facilities are provided.

Section 259

259. (1) Where there is danger of injury to an employee from material falling from a conveyor, an employer shall ensure that sheet metal or screen guards are installed under or along side the conveyor if it is not entirely enclosed so as to prevent the material from falling.

(2) Where there may be danger of injury to an employee who is in proximity to a belt conveyor, an employer shall ensure that the conveyor is provided with adequate safeguards extending 1 m from the pulleys and along the sides of the conveyor.

(3) An employer shall ensure that an inclined bucket conveyor is enclosed with a solid safeguard that has one or more wire glass windows and that is not less than 2.1 m in height extending to the full height of the conveyor.

(4) An employer shall ensure that a screw conveyor is placed in metal troughs fitted with secured covers of not less than 3 mm thick metal plates in removable sections or of other material that provides equivalent protection.

(5) An employer shall ensure that when a screw conveyor is fed from the floor level, adequate safeguards are provided around the opening.

Section 260

260. (1) An employer shall ensure that an enclosed or pneumatic conveyor used for carrying combustible or flammable material of an explosive nature is provided with an adequate explosion prevention system or with safety relief vents leading as directly as possible to the outside air and not connecting with any chimney pipe, vent or flue used for any other purpose.

(2) Where non-escape of materials being carried on an enclosed conveyor is essential, an employer shall ensure that safety relief vent outlets on the conveyor are provided with counter-balanced relief valves.

(3) An employer shall ensure that a fan for a pneumatic conveyor is

(a) made of fire resistive material,

(b) secured to a substantial support or foundation,

(c) located, arranged and guarded so as to afford ready and safe access for maintenance, and

(d) provided with remote controls in addition to normal operating controls.

(4) Where flammable materials are passed through the fan of a pneumatic conveyor, an employer shall ensure that the blades and spiders of the fan are made of non-ferrous material and the casing of the fan is lined with non-ferrous material.

(5) An employer shall ensure that intake openings of fans for a pneumatic conveyor are protected with metal screens or gratings.

(6) Where material is fed by hand into a pneumatic conveyor 300 mm in width or larger, an employer shall ensure that precautions are taken to prevent an employee from being drawn into the opening.

Section 261

261. (1) An employee shall not

(a) stand on the supporting frame of a conveyor while loading or unloading the conveyor or when clearing blockages on the conveyor unless the conveyor is stopped and locked out, or

(b) ride on a conveyor.

(2) An employee shall remove heavy or bulky articles by hand from a moving conveyor at designated stations only.