Pits and Quarries

Pits and quarries support many industries by providing aggregates, such as loose material found in pits, and solid material, found in quarries. Working in pits and quarries poses many risks such as slides, cave-ins, being struck by powered mobile equipment and falling materials, vehicle rollovers, exposure to excessive noise, working near conveyors and moving parts, and exposure to dust.

As an employer/owner of pits or quarries, you must:

- Submit detailed drawings with specifications for the pit or quarry development to the chief compliance officer, when required.

- Ensure that a haulage road in a pit or quarry is designed, constructed and maintained:

- To minimize hazards from the slipping or skidding of vehicles.

- To enable vehicles to pass each other safely.

- So that grades do not exceed the design capacity for vehicles that are used.

- When an employee is required to walk, provide a walkway from the working level to the surface, or

- When the walkway is inclined at more than 20 degrees and less than 50 degrees to the horizontal, provide stairways or ladderways, or when the walkway is inclined more than 50 degrees to the horizontal provide ladderways.

- Ensure that material excavated from a pit or quarry is piled at a safe distance from the edge of the pit or quarry to prevent materials collapsing into the pit or quarry or causing ground failure.

- Take precautions to keep vehicles at a safe distance from the edge of the stockpile.

- Ensure that unconsolidated overburden is at least 7 m from the edge of the pit or quarry or a sufficient distance to prevent it from falling into the pit or quarry and is sloped to its natural angle of repose.

- Ensure that utility poles, posts, and similar structures within 3 m of a pit that is more than 1.2 m deep are supported or removed.

Work Procedures for Quarries

As an employer/owner of the quarry you must:

- Notify the chief compliance officer of the intent to begin or resume operations in the quarry at least two weeks before the work starts, or if resuming after no activity for four months or more.

- Ensure that the person in charge of the shift:

- Ensure that the daily examination and record book is available on request to a joint health and safety committee or health and safety representative, if any, and to an officer on request.

- Ensure that no employees work close to a quarry face until the face has been examined and declared safe before the start of each shift by the person in charge of the shift.

- Ensure that a quarry 20 m deep or over is worked in benches that are not more than 20 m high unless the side cast method of stripping is used.

Example of a Dragline

- Ensure that the quarry is worked in benches where the walls of a quarry under 20 m cannot be excavated safely.

- Construct a berm or ledge of sufficient width to catch and retain rocks that fall from the bench or face above.

- Not permit loose materials to accumulate on a berm or ledge that may endanger a person on a lower bench in the quarry.

- Ensure that there is no undercutting of the working face of a quarry except where a tunnelling method is used to remove rock.

- When enclosing ground is not secure when the tunneling method is used to remove rock, ensure that:

- Ensure that all adits, declines, and tunnel opening 20 m or more from the collar are protected against slides or other runs of materials where the wall of the quarry exceeds 37.5 degrees from the horizontal.

Example of an Adit

Work Procedures of Pits

As an employer of the pit you must:

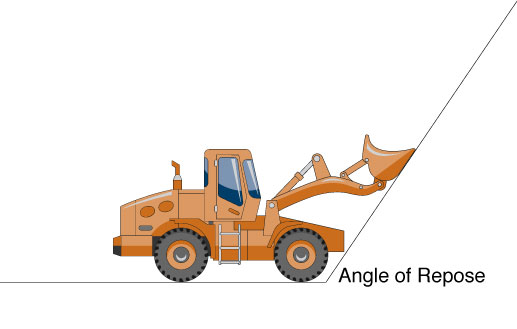

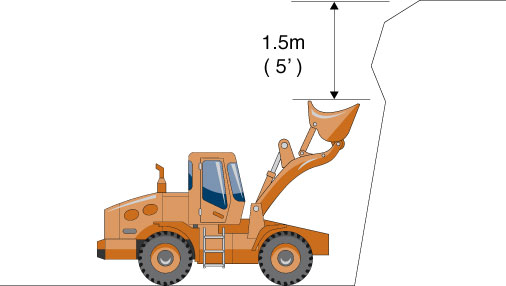

- Ensure that the working face of a pit in which material is being removed by powered mobile equipment is sloped at its angle of repose, or benched to limit the vertical height to not more than 1.5 m above the maximum reach of the equipment in use.

202(a)

202(b)

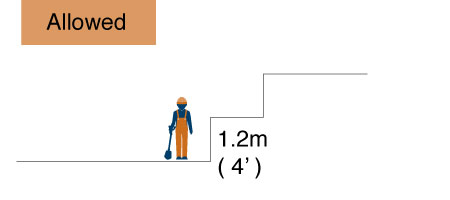

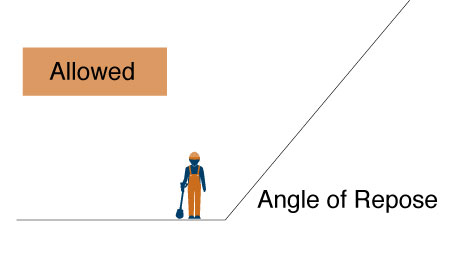

- Ensure that the working face of a pit in which material is being removed by means other than powered mobile equipment is sloped at its angle of repose, or benched to limit the vertical height of the working face to not more than 1.2 m.

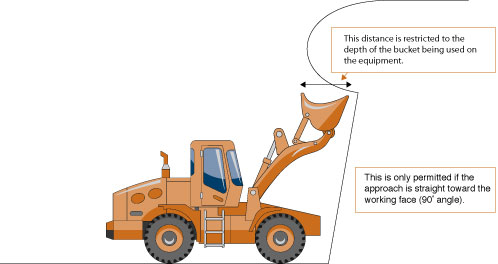

- Ensure that undercutting by powered mobile equipment at the face of a pit is restricted to the depth of the bucket of the equipment in use, and permitted only when the equipment operator's approach is at a 90 degree angle to the face.

Only permitted if the approach is directly straight toward the working face (90 degree angle).

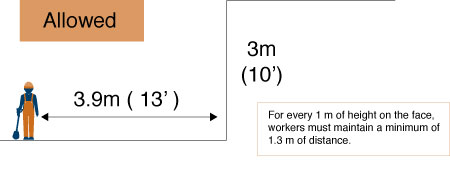

- Ensure that an employee on foot comes no closer than 1.3 times the height of the working face unless the working face is sloped at its angle of repose or is benched to limit the vertical height of the working face to not more than 1.2 m.

- Ensure that the top of a pit is adequately marked to indicate its location.

- Ensure that when powered mobile equipment is used to push material in a pit, or a body of water at the bottom of a pit or quarry, a berm is created to indicate to the operator the safe limit to where equipment can advance. The operator must not advance the equipment past the berm.

As the person in charge of a shift of the quarry, you must:

- Read the daily examination and record book entries made by the person in charge of the previous shift and sign it before assigning work.

- Record the results in a daily examination and record book.

- Record all areas worked and all unusual occurrences or hazardous conditions.

- Ensure that the employees are wearing proper personal protective equipment, including hearing protection.

Additional concerns in pits and quarries:

- The employer must take measures to protect against any risks to employees from dust, if present.

- Because pits and quarries can be located in remote areas, the employer must ensure that drinking water and washrooms are available.

- The employer must provide proper lighting for the employees to perform their work safely, if work is to be done in low natural light conditions.

- The employer must ensure proper drainage of pits or quarries, to prevent water accumulating to a hazardous level.

- The employer must provide adequate guarding around conveyors and equipment.

While the employer is ultimately responsible for all the provisions mentioned above, the supervisor has a vital role to play in the safety of their teams. As a supervisor, you must:

- Acquaint your employees with the hazards and control measures associated with their work

- Provide the information and instruction necessary to ensure their health and safety

- Enforce company safety rules, programs, codes of practice and procedures, including ensuring employees comply with the requirements below.

Examples: sand and gravel

Examples: limestone and granite

“pit” means a work or undertaking for the purpose of opening up, proving, removing or extracting any unconsolidated metallic or non- metallic mineral or mineral bearing substance, rock, earth, clay, sand or gravel by means of an open excavation in order to supply it for construction, industrial or manufacturing purposes.

“quarry” means a work or undertaking for the purpose of opening up, proving, removing or extracting consolidated rock by means of an open excavation in order to supply it for construction, industrial or manufacturing purposes and includes an open pit mine.

Detailed drawings can be submitted by email at: compliance.conformite@ws-ts.nb.ca, by Fax: 1 888 629-4722 or contact the Toll Free Number for additional assistance: 1 800 999-9775

Should WorkSafeNB have any concerns regarding the safety of employees working in or around a pit or quarry, the regulation provides the authority to the Chief Compliance Officer to require that drawings including details of development be provided by the pit or quarry owner and the employer responsible for the pit or quarry. As a result, it is highly recommended that the drawings be prepared and be readily available in the event such a request is made by the Chief Compliance Officer.

Ensure proper drainage, materials used for the road shall compact properly and not become too soft when exposed to water, etc.

Ladderway: a vertical passageway with ladders.

“angle of repose” means the angle with the horizontal at which material will no longer flow freely

By using this method, aggregates are removed in the quarry with a dragline that digs down from the surface and moves the aggregates to the surface.

Adit: A horizontal passage leading into a mine for the purposes of access or drainage.

It is the responsibility of the owner and the employer to ensure the existence of a pit is marked with signage, barriers, or other appropriate means to alert persons in the area.

General Regulation - Occupational Health and Safety Act

N.B. Reg. 91-191

Part XIV PITS AND QUARRIES

Section 190

190. Where required to do so by the Chief Compliance Officer, an owner of a pit or quarry and an employer shall submit detailed drawings with specifications for the development of the pit or quarry to the Chief Compliance Officer.

Section 191

191. An owner of a pit or quarry and an employer shall each ensure that a haulage road in a pit or quarry is designed, constructed and maintained

(a) to minimize hazards from the slipping or skidding of vehicles,

(b) to enable vehicles to pass each other safely, and

(c) so that grades do not exceed the design capacity of vehicles that are used in the pit or quarry.

Section 192

192. (1) Where an employee is required to walk from the working level of a pit or quarry to the surface, an employer shall provide a walkway from the working level to the surface for the employee.

(2) Where a walkway under subsection (1) is inclined at more than 20 degrees and less than 50 degrees to the horizontal, an employer shall provide stairways or ladderways.

(3) Where a walkway under subsection (1) is inclined at more than 50 degrees to the horizontal, an employer shall provide ladderways.

Section 193

193. (1) An employer shall ensure that material excavated from a pit or quarry is piled at a distance from the edge of the pit or quarry so that the material does not subside into the pit or quarry or cause ground failure.

(2) Where material excavated from a pit or quarry is dumped from a vehicle to a stockpile, an employer shall ensure that precautions are taken to keep the vehicle at a safe distance from the edge of the stockpile.

Section 194

194. An employer shall ensure that unconsolidated overburden

(a) is moved from the edge of a pit or quarry a sufficient distance to prevent the overburden from falling into the pit or quarry,

(b) is at least 7 m from the edge of the pit or quarry, and

(c) is sloped to its natural angle of repose.

Section 195

195. An employer shall ensure that utility poles, posts and similar structures are supported or removed if they are within 3 m of a pit that is more than 1.2 m deep.

Section 196 Work Procedures for Quarries

196. Where quarrying activities are initially started or where activities are resumed after a cessation of production of four months or more, the owner of the quarry or the employer shall notify the Chief Compliance Officer of the intention to begin or resume operations in the quarry at least two weeks before the operations are to begin or resume.

Section 197

197. (1) An employer shall ensure that an examination of all work faces in a quarry is made at the beginning of each operating shift and the results are recorded by the person in charge of the shift in a daily examination and record book together with a daily recording of all areas worked and of all unusual occurrences or hazardous conditions.

(2) The person in charge of a shift shall read the record in the daily examination and record book made by the person in charge of the previous shift and sign it before assigning work for the shift about to begin.

(3) An employer shall ensure that the daily examination and record book referred to in subsection (1) is available on request to a committee or health and safety representative, if any, and to an officer on request.

(4) An employer shall ensure that no employee works close to a face of a quarry until the face has been examined and declared safe before the start of each shift by the person in charge of the shift.

[N.B. Reg. 2022-27, s. 33]

Section 198

198. (1) An employer shall ensure that a quarry 20 m or over in depth is worked in benches that are not more than 20 m high.

(2) Subsection (1) does not apply when the side cast method of stripping is used.

(3) Where the walls of a quarry under 20 m cannot be excavated safely, an employer shall ensure that the quarry is worked in benches.

Section 199

199. (1) An employer shall ensure that a berm or ledge in a quarry is constructed of sufficient width to catch and retain rocks that fall from the bench or face above.

(2) An employer shall ensure that loose material that may endanger a person on a lower bench in a quarry is not permitted to accumulate on a berm or ledge in the quarry.

Section 200

200. (1) An employer shall ensure that there is no undercutting of the working face of a quarry except where a tunnelling method is used to remove rock.

(2) Where a tunnelling method is used to remove rock in a quarry and the enclosing ground is not secure, an employer shall ensure that

(a) every tunnel in which work is being carried on or through which persons pass is securely cased, lined, timbered, screened, rockbolted or otherwise made secure, and

(b) no person is allowed to go beyond a cased, lined, timbered, screened, rockbolted or otherwise secured ground.

Section 201

201. Where the wall of the quarry exceeds 37.5 degrees from the horizontal, an employer shall ensure that all adits, declines and tunnel openings collared within the wall are protected against slides or other runs of material and that such protection is established once the distance of the adits, declines and tunnel openings from the collar have reached 20 m.

Section 202 Work Procedures for Pits

202. Where material in a pit is being removed by means of powered mobile equipment, an employer shall ensure that the working face of the pit is

(a) sloped at its angle of repose, or

(b) benched to limit the vertical height to not more than 1.5 m above the maximum reach of the equipment in use.

Section 203

203. Where material in a pit is being removed by means other than powered mobile equipment, an employer shall ensure that the working face of the pit is

(a) sloped at its angle of repose, or

(b) benched to limit the vertical height of the working face to not more than 1.2 m.

Section 204

204. An employer shall ensure that undercutting by means of powered mobile equipment at the face of a pit is

(a) restricted to the depth of the bucket of the powered mobile equipment in use, and

(b) permitted only when the approach by the operator of the powered mobile equipment is at a 90 degree angle to the face.

Section 205

205. An employer shall ensure that an employee on foot comes no closer to the working face of a pit than 1.3 times the height of the working face unless the working face is sloped at its angle of repose or is benched to limit the vertical height of the working face to not more than 1.2 m.

Section 206

206. An owner of a pit and an employer shall each ensure that the top of a pit is adequately marked to indicate the existence of the pit.

[N.B. Reg. 2001-33, s. 60]

Part XV MATERIALS HANDLING EQUIPMENT AND PERSONNEL CARRYING EQUIPMENT

Section 230.1

230.1 (1) In this section,

"berm" means a mound or pile of material raised above the surrounding surface.

(2) Where powered mobile equipment is used to push material into a body of water, pit, excavation or other cavity, an employer shall ensure that a berm is created between the equipment and the water, pit, excavation or other cavity to indicate to the operator the safe limit to which the powered mobile equipment may advance, and an operator of powered mobile equipment shall not advance the equipment past the berm.

(3) Where powered mobile equipment is used to push material into a frozen body of water, an employer and an operator shall each ensure that the ice is broken before any material is pushed into the water.

[N.B. Reg. 2001-33, s. 83]