Logging and Silviculture

Logging activities involve exposure to many hazards including:

- The tools used, such as chainsaws and brush saws.

- The activities performed, such as tree felling, off-road driving, lockout/tagout, working remotely, or working at heights.

- Hazardous products and fuels.

- Weather extremes (heat, cold, lightning), working alone, lack of emergency services, wildlife, insects, and biological hazards (West Nile virus, Lyme disease).

Logging operations are defined in New Brunswick as any work connected with the harvesting of trees, and includes the transportation, felling, delimbing, cutting to length, processing on site, and extraction of trees.

As an employer of a logging operation, you must:

- Make sure each employee who uses tools, equipment, machines, devices, and materials is competent and has received training that is acceptable to the Commission.

- Make sure an effective communication plan is in place, and that every employee follows the communication plan.

- Before employees start work in a new work area, make sure that a safety meeting is held to inform them of any hazards in that area and actions have been taken to eliminate or minimize the hazards.

- Inform any employee who did not attend the safety meeting of any hazards in that area and the actions taken to eliminate or minimize the hazards.

- Develop a code of practice that addresses environmental conditions that are hazards for employees, including (but not limited to) weather conditions, topography (landscape), wildlife, and biological hazards.

- In addition to following the general requirements for personal protective equipment, make sure employees wear:

- high visibility safety apparel that meets at least the requirements of CSA Standard CSA-Z96-15 “High-Visibility Safety Apparel” or a standard offering equivalent or better protection.

- high-visibility head wear

- when operating a chainsaw, wears

- safety footwear that meets the requirements of CSA-Z195:14 (Reaffirmed 2019) “Protective Footwear” or a standard offering equivalent or better protecton, and has chainsaw protection on the top and sides, and has non-slip soles

- leg protection (that is permanently labelled to indicate which standard it meets)

- safety footwear that is corked, caulked, or spiked when the employee is working on a slope that is greater than 30%

When an employee operates a chainsaw, brush saw, or clearing saw, they will:

- Not work alone.

- Not girdle trees.

- Not refuel the saw while the engine is operating, or near a source of ignition.

- Refuel only from a container that is NOT made of glass with a spout or funnel.

- Move the saw at least 3 metres (10 feet) away from where it was refuelled before starting the engine.

- Carry or keep close the pressure bandage provided by the employer.

Chainsaws

As the owner of a chainsaw, you must ensure

- The chainsaw meets at least the requirements of CSA Z652.1-11 “Chain Saws” and CSA Z62.3-11 (Reaffirmed 2016) “Chain Saw Kickback” or a standard offering equivalent or better protection.

- The chainsaw is:

- only used with a safety chain that is filed according to the manufacturer’s instructions

- equipped with an adequate chain brake, and

- is fitted only with component parts according to the manufacturer

When an employee is operating a chainsaw, they must:

- Stop the motor before carrying the saw from one location to another, or before adjusting the chain.

- Adjust the saw following the manufacturer’s instructions.

- Hold the saw against a solid object below waist level when starting a cold saw.

- Hold the saw with both hands and stand on a solid base when operating it.

- Immediately remove a defective saw until it is repaired.

- Not pull the cord with the other hand on the throttle mechanism while starting.

- Not operate the saw above shoulder height.

- Not climb on or work under a felled tree.

As an employer, you must make sure:

- That an employee operates a hydraulically driven chainsaw according to the manufacturer’s instructions.

- The employee does not operate the chainsaw so that the saw bar is directly in line with the cab or other people.

- The hydraulically driven chainsaw is maintained according to the manufacturer’s instructions.

Brush Saw or Clearing Saw

When an employee is operating a brush saw or clearing saw, they must:

- Operate and maintain the saw according to the manufacturer’s recommendations.

- Only use blades and component parts as stated by the manufacturer.

- Make sure the saw has an adequate blade guard.

- Stay at least 10 metres (32 feet) away from any other person while operating the saw.

- Inspect the blade regularly, and file it when needed.

- Replace the blade when signs of cracks or fractures are first seen.

- Use a harness that is suitable for that saw.

- Make sure the harness is well maintained, properly adjusted, and has a properly functioning emergency release.

- Stop the engine before making any manual adjustments, cleaning, clearing of debris or other work on the blade or blade guard.

- Not start the saw while it is attached to the harness.

Working Alone

As an employer, you must ensure any employee using a chainsaw, brush saw, or clearing saw, (as outlined in New Brunswick’s First Aid Regulation 2004-130, )

- Knows the emergency communication procedures and transportation procedures.

- Is accompanied by a person who has a valid first aid workplace certificate.

Tree Felling

Before starting to fell a tree, an employee must ensure that:

- All standing dead trees and other potential hazards are removed from the work area.

- There is a clear path of retreat for safety (escape route).

- All other persons are at least 40 metres (131 feet) away from the felling area.

- When a person is assisting during a trail-cut operation, the assistant has moved at least 3 metres (10 feet) away from the tree at a 45-degree angle from the direction opposite in which the tree is intended to fall.

The employer and employee must use powered mobile equipment to fell a standing dead tree, if not possible a chainsaw may be used. . The operation of the chainsaw must meet the requirements of the General Regulations and include to: .

- Have the employee stand straight and tall to reduce the exposure to their neck and back.

- Use a lever instead of a wedge to avoid hitting the tree.

If the standing dead tree cannot be felled by powered mobile equipment or a chainsaw, the employer must:

- Develop a written safe work procedure.

- Make sure employees receive adequate instruction and training for the task.

- Make sure employees follow the safe work procedures.

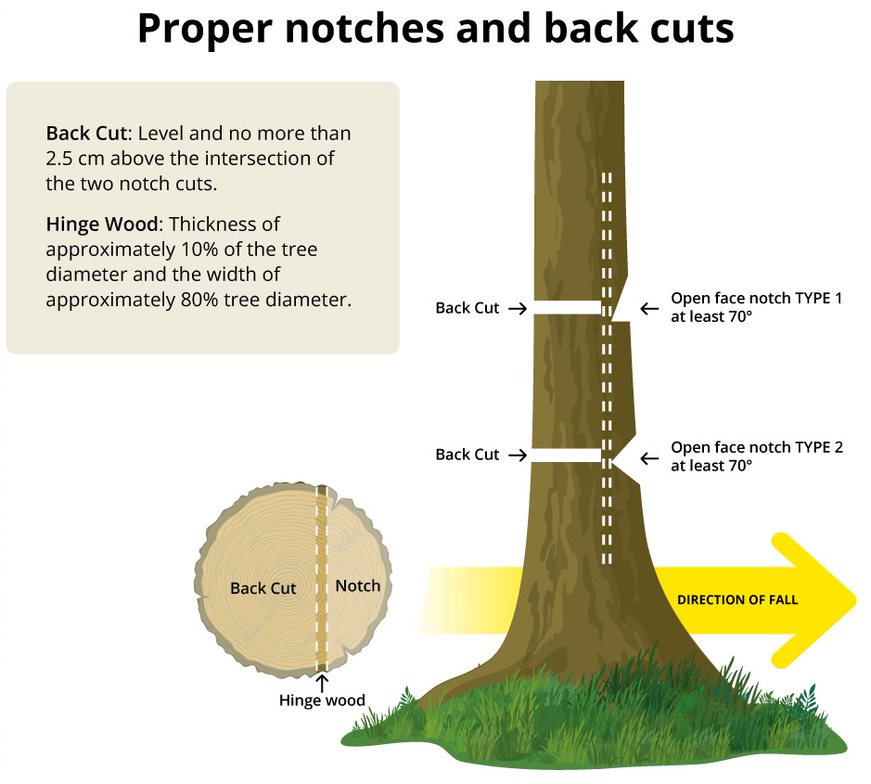

As an employee, when felling a tree, you must properly notch and back cut the tree as shown in Figure 1:

Figure 1: Proper Notches and Back Cuts

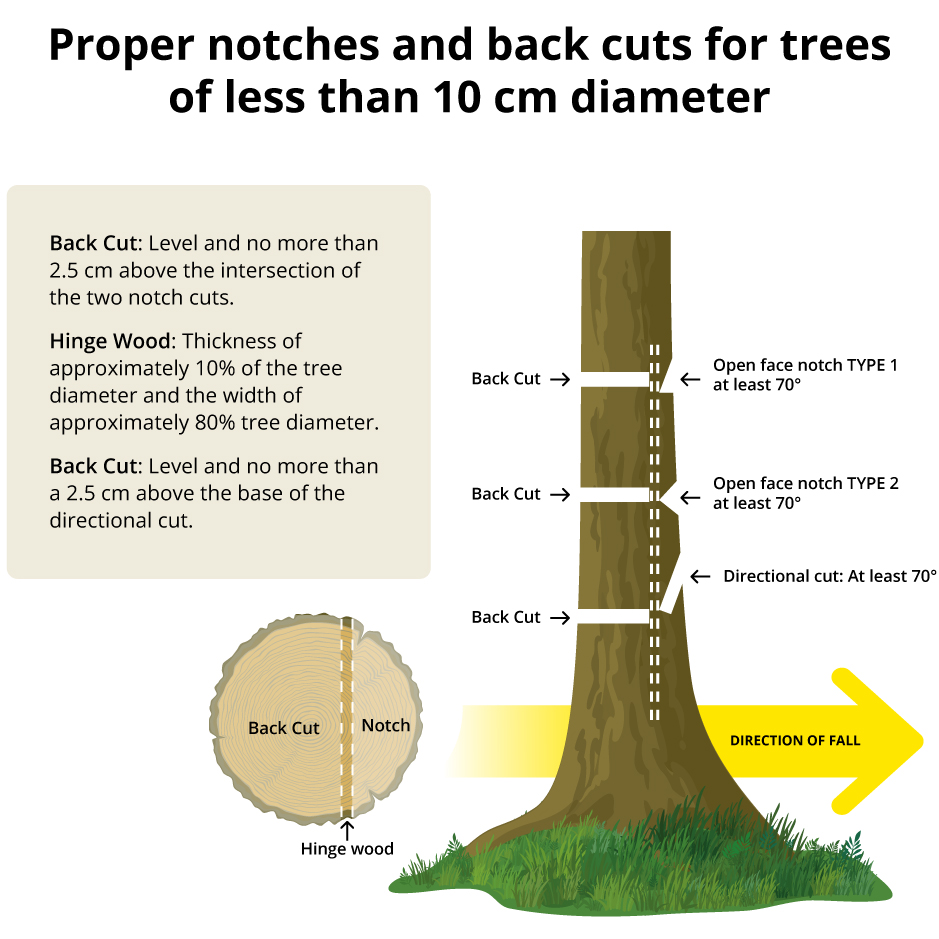

When an employee is felling a tree that is less than 10 centimetres (4 inches) in diameter, they must make a hinge by using the notch and back-cut method shown in Figure 2 or by following these steps:

- Make a directional cut that is at least 70 degrees.

- Make a back cut that is level and not more than 2.5 cm (1 inch) above the base of the directional cut.

- Leave a hinge that is at a thickness of about 10% of the tree’s diameter, and a width of about 80% of the tree’s diameter.

Figure 2: Proper Notches and Back Cuts for Trees of less than 10 cm diameter

Employees must also:

- Use a felling lever or wedge, as required.

- Complete the felling once you have started.

- Move at least 3 metres (10 feet) away from the tree at a 45-degree angle from the direction opposite in which the tree is intended to fall.

- When felling a tree on a slope that is more than 30%, use an escape route that is perpendicular to the slope, and not in the direction of the fall.

- When the tree becomes lodged

- stay in the area until the lodged tree is removed, or clearly mark as a hazardous area that is at least as large as two tree lengths from the stump of the lodge tree.

- make sure the lodged tree is removed as soon as possible by using powered mobile equipment if possible, and without a person climbing on the tree, having another tree felled on it, or having the supporting tree cut.

- do not do any other work within the hazardous area.

- Not cut a spring pole in a way that will create a danger to anyone.

Delimbing and bucking

When an employee delimbs a fallen tree, they must make sure:

- The tree is resting solidly on the ground.

- No person walks on the tree trunk while it is being delimbed.

- To work on the uphill side whenever possible.

- When using a chainsaw:

- the tip of the guidebar is not used for delimbing.

- the saw is not positioned directly in front of the operator.

- the saw is not used with motions that bring the saw towards the operator.

When an employee is bucking a tree, they must make sure:

- Both feet are on the ground.

- The tree is resting solidly on the ground.

- The saw is NOT positioned directly in front of the operator.

Powered Mobile Equipment

The employer must ensure:

- The skidder or forwarder has a completely enclosed operator’s cab that is designed to protect objects from entering the cab and will prevent the operator or passengers in the cab from being thrown outside.

- The powered mobile equipment has at least two safe and unobstructed ways to enter and exit that are not on the same side of the cab, and that these means are inspected visually at least daily and tested monthly. If a defect or hazard is found, make sure no one uses the powered mobile equipment until the defect or hazard has been eliminated.

- When loading or unloading powered mobile equipment onto or off of a transport vehicle

- the manufacturer’s specifications for both the powered mobile equipment and transport vehicle are followed.

- the load is parallel to the transport vehicle.

- no person is within the rollover area of the powered mobile equipment.

- When transporting the powered mobile equipment, both the employer and operator must make sure:

- that articulated powered mobile equipment is restrained so it does not articulate when being transported.

- accessory equipment and attachments are completely lowered and secured to the transport vehicle.

- the total working load limits from all tiedowns is at least 50% of the weight of the powered mobile equipment being transported.

- when powered mobile equipment is used, another employee is within 600 metres (1968 feet) of the employee operating the equipment (except if working alone as noted below), or the employee who operates powered mobile equipment alone contacts a person designated by the employer at least every two hours, and in either case the employee contacts the communication centre before exiting the cab when the employee exits the cab to perform work on the equipment.

Employees (other than the operator of the powered mobile equipment) must not work closer than 50 metres (164 feet) from the powered mobile equipment when it is being used, except when assisting an employee operating a skidder.

When an employee is operating a skidder, they must:

- Direct people assisting them to stand clear of any trees or logs after they have been attached to the skidder.

- Not winch any trees or logs until the assistant is standing clear and in the opposite direction in which the load will be winched and has signalled to the operator they are clear.

- Operate the winch from the seat unless it is designed to be operated by remote control

- Keep the wheel chains properly adjusted.

- Lower the blade and apply the brakes when winching.

- Verify the assistant’s location before moving the skidder.

Hauling logs

As an employer, you must ensure that when a wire rope is used to haul logs, the rope is replaced when there are signs of wear or damage, and cable cutters are readily available.

Employees must attach the wire rope no farther than 1 metre (3 feet) from the end of the log.

Cable logging systems must meet the requirements stated in the General Regulations , including that the system is installed, inspected, operated, and maintained according to section 7-2.4 of ASME Standard B30.7-2011 (Winches, or another standard that offers the same or better protection).

As an employer, you must ensure:

- The cable logging system is equipped with remote controls that have a fail-safe mechanism to prevent the operation of more than two remote controls at the same time.

- All employees receive training on how to use the cable logging system.

Woods Roads

As an employer, you must make sure that a woods road:

- Has wide sections for passing if the road only has one travelling lane.

- Has stop signs that are easy to see located at intersections.

- Has signs that ward of dangerous curves, blind hills, or steep hills that are easy to see and allow for enough reaction time.

- Is kept in safe condition.

- That is intended to be built near an electrical utility line is not started until the authority owing or operating the energized electrical utility line is notified about the location of the woods road, and the time and duration of the planned work.

- Is not built any closer to an energized electrical utility line than the distances provided by the authority owning or operating the line.

- Is constructed as close as possible to a logging area to allow for reasonable access and efficient evacuation if there is an emergency.

The employer must make sure that adequate warning signs are posted and are visible in both directions when a logging operation, silviculture operation, or road construction operation is occurring and interferes with the flow of vehicle traffic.

The employer must also make sure that bridges on a woods road:

- Are constructed according to a plan approved by an engineer.

- Have the load capacity posted in a way that is easy to see 30 meters from both end of the bridge.

- Have a warning sign posted that is easy to see 90 meters away from the bridge if the bridge is not visible from that distance.

- That are over 1.2 meters in height have bumpers at least 250 mm high that run the length of the bridge or culvert on both sides.

- Have a hazard marker located on the corner of the bridge or culvert with the bottom maker at least more than 1.5 metres and no more than 2.5 metres above the travelled portion of the road.

- Have a sign that is easy to see on the side of the road at least 150 metres from the bridge or culvert that warns of a narrow passage (if the width of the bridge or culvert is less than the woods road).

The employer must make sure the sign or hazard marker on a woods road is made of light reflective material and is of a size that makes it clearly visible under normal driving conditions.

The operator of the vehicle must keep the headlights on while driving on a woods road. The operator must also drive within the speed limit as set by the owner of the woods road, and according to the traffic, environmental conditions, and condition of the woods road.

Loading Operations

Both the employer and employee must make sure that a truck load of logs that travels on a woods road is secure. To secure a load:

- The truck must be equipped on the top and rear of the cab with structural protection that is strong enough to restrain the cargo.

- Use visible means of identification when the rear overhang is more than 1 metre

- Use at least two tie-downs to restrain each stack of wood.

- Make sure that stakes that are not permanently attached to the vehicle frame or bunk are secured to stop the stakes from separating from the vehicle while travelling.

- The employer must make sure an employee does a walk around inspection of the load before leaving the work area, at check points, before entering the highway, and before removing load binders at the off-loading site. Check points along the woods road must be designated by the employer and marked with signs.

- Do not let the weight of the load create a hazard.

While the employer is ultimately responsible for all the provisions mentioned above, the supervisor has a vital role to play in the safety of their teams. As a supervisor, you must:

- Acquaint your employees with the hazards and control measures associated with their work.

- Provide the information and instruction necessary to ensure their health and safety.

- Enforce company safety rules, programs, codes of practice and procedures, including ensuring employees comply with the requirements below.

As an employee, you must:

- Follow any instruction, education or training provided by your employer about logging, and use any equipment that is required (including personal protective equipment).

- Be aware of changing conditions.

- Report any hazards to your employer or supervisor.

Viewing CSA Standards as Referenced in NB Legislation

Certain CSA standards are available for online viewing or purchase from the CSA Group.

To access these, you must first create an account with CSA Communities

Once you are logged in, click on the "OHS Standards / View Access" option.

Click on New Brunswick to see the CSA Standards as referenced in N.B. legislation.

General Regulation - Occupational Health and Safety Act

N.B. Reg. 91-191

Part XXI LOGGING AND SILVICULTURE OPERATIONS

Section 345

345. With respect to the tools, equipment, machines, devices and materials that an employee is to use, an employer shall ensure that

(a) each employee is competent to use them, and

(b) each employee has received training that is acceptable to the Commission.

[N.B. Reg. 2022-27, s. 50]

Section 345.1 Communication plan - logging operations

345.1 An employer shall ensure that an effective communication plan is in place for employees involved in a logging operation and every employee shall follow the communication plan.

[N.B. Reg. 2022-27, s. 51]

Section 345.2 Initial safety meeting

345.2 (1) Before employees start work in a new work area, a safety meeting shall be held to inform the employees of any hazards in that area and the actions to be taken to eliminate or minimize the hazards.

(2) If an employee fails to attend the safety meeting, the employer shall ensure the employee is informed of any hazards in the work area and the actions to be taken to eliminate or minimize the hazards.

[N.B. Reg. 2022-27, s. 51]

Section 345.3 Code of practice - environmental conditions

345.3 An employer shall develop a code of practice to protect employees from possible hazardous situations caused by environmental conditions, including:

(a) weather conditions;

(b) topography;

(c) wildlife contacts; and

(d) biological hazards.

[N.B. Reg. 2022-27, s. 51]

Section 345.4 Powered mobile equipment

345.4 (1) An employer shall ensure that powered mobile equipment is equipped with at least two safe and unobstructed means of access and egress that are not located on the same side of the cab of the powered mobile equipment.

(2) An employer shall ensure that the means of access and egress is inspected visually at least daily and tested monthly and, if the inspection reveals a defect or hazard, the employer shall ensure that no one uses the powered mobile equipment until the defect or hazard has been eliminated.

(3) An employer shall ensure that powered mobile equipment is equipped with cleats or corks when woods roads are frozen.

[N.B. Reg. 2022-27, s. 51]

Section 345.5 Transportation of powered mobile equipment

345.5 (1) When loading or unloading powered mobile equipment onto a transport vehicle, an employer and an operator shall ensure that

(a) the manufacturer’s specifications for the powered mobile equipment and the transport vehicle are followed,

(b) the load is parallel to the transport vehicle, and

(c) no person is within the rollover area of the powered mobile equipment.

(2) When transporting powered mobile equipment by transport vehicle, an employer and an operator shall each ensure that

(a) articulated powered mobile equipment are restrained in a manner that prevents articulation while the transport vehicle is in transit,

(b) accessory equipment and attachments are completely lowered and secured to the transport vehicle,

(c) the powered mobile equipment is restrained by at least four tie downs that are attached, as close as is practicable, at the front and rear of the transport vehicle or to mounting points on the transport vehicle that are specifically designed for that purpose, and

(d) each tie down has a working load limit of at least 2,268 kg and the sum of the working load limits is equal to or greater than 50 % of the weight of the powered mobile equipment

[N.B. Reg. 2022-27, s. 51]

Section 345.6 Skidder or forwarder

345.6 An employer shall ensure that a skidder or forwarder is provided with a completely enclosed operator’s cab that is designed to prevent objects from intruding into the cab and to prevent the operator and any passengers in the cab from being thrown outside the cab.

[N.B. Reg. 2022-27, s. 51]

Section 346 Protective Equipment

346. An employer shall, in addition to complying with the appropriate requirements for protective equipment under Part 7, ensure that

(a) an employee wears

(i) high visibility safety apparel that meets the requirements of CSA standard Z96-15 (R2020), High-visibility safety apparel or a standard offering equivalent or better protection, and

(ii) high visibility safety headgear,

(b) an employee who operates a chain saw wears

(i) safety footwear that meets the requirements of CSA standard Z195:14 (R2019), "Protective Footwear" or a standard offering equivalent or better protection, has chain saw protection on the top and sides and has non-slip soles, and

(ii) leg protection that has a label permanently affixed to the outer surface of the leg protection indicating the standard it meets, and

(c) an employee who is working on a slope that is greater than 30% wears safety footwear that is corked, caulked or spiked.

[N.B. Reg. 2001-33, s. 114; 2020-35, s. 40; 2022-27, s. 52; 2022-79, s. 92; 2024-38, s. 106]

Section 347

347. An employee shall, in addition to complying with the appropriate requirements for protective equipment under Part VII, wear the protective equipment required in section 346.

Section 348 Chain Saws, Brush Saws and Clearing Saws

348. (1) An owner of a chain saw shall ensure that the chain saw meets the applicable requirements of CSA standard Z62.1-11, "Chain saws" or a standard offering equivalent or better protection and CSA standard Z 62.3-11 (R2021) "Chain saw kickback" or a standard offering equivalent or better protection.

(2) An owner of a chain saw shall ensure that the chain saw

(a) is used only with a safety chain that is filed according to the manufacturer's specifications,

(b) is equipped with an adequate chain brake, and

(c) is fitted only with component parts specified by the manufacturer.

[N.B. Reg. 2001-33, s. 115; 2022-27, s. 53; 2022-79, s. 93]

Section 349

349. An employee who operates a chain saw shall

(a) stop the motor before carrying the saw from one location to another,

(b) stop the motor before adjusting the chain,

(c) adjust the saw according to the manufacturer's specifications so that the chain is stopped while the motor is idling,

(d) immediately remove a defective saw from use until repaired,

(e) start the saw when it is cold by holding it against a solid object below waist level,

(f) not start the saw by pulling on the cord while the other hand engages the throttle mechanism,

(g) hold the saw in both hands while operating it,

(h) not operate the saw above shoulder height,

(i) stand on a solid base when operating the saw, and

(j) not climb on or work under a felled tree.

Section 349.1 Hydraulically driven chain saw

349.1 (1) An employer shall ensure that an employee operates a hydraulically driven chain saw in accordance with the manufacturer’s specifications and does not operate the chain saw in a way that the saw bar is directly in line with the cab or other persons.

(2) An employer shall maintain a hydraulically driven chain saw in accordance with the manufacturer’s specifications.

[N.B. Reg. 2022-27, s. 54]

Section 350

350. An employee who operates a brush saw or a clearing saw shall

(a) operate and maintain the saw in accordance with the manufacturer's specifications,

(b) ensure that the saw is equipped with an adequate blade guard,

(c) maintain a minimum 10 m distance from any other person while operating the saw,

(d) regularly inspect the blade and file it when necessary,

(e) replace the blade at the first sign of cracks or fractures,

(f) fit the saw only with blades and component parts as specified by the manufacturer,

(g) use a harness suitable for use with the saw,

(h) ensure that the harness is well maintained and properly adjusted and that the emergency release on the harness functions properly,

(i) stop the engine before any manual adjustment, cleaning, clearing of debris or other work is carried out on the blade or blade guard, and

(j) not start the saw while it is attached to the harness.

Section 351

351. (1) An employer shall ensure that an employee who operates a chain saw, brush saw or clearing saw is knowledgeable of the emergency communication procedure and the transportation procedure set out in New Brunswick Regulation 2004-130 under the Act and is accompanied by a person who holds a valid First Aid Workplace Certificate in accordance with that Regulation.

(2) An employer shall ensure that an employee who operates a chain saw, brush saw or clearing saw has

(a) a suitable fire extinguisher or a round point shovel readily available,

(b) suitable first aid supplies readily available, and

(c) a pressure bandage.

[N.B. Reg. 2022-27, s. 55]

Section 352

352. An employee who operates a chain saw, brush saw or clearing saw shall

(a) not work alone,

(b) not girdle trees,

(c) not refuel the saw while the engine is operating,

(d) move the saw at least 3 m from where it was refuelled before starting the engine,

(e) refuel only from a non-glass container with spout or funnel,

(f) not refuel the saw near any source of ignition, and

(g) carry or keep close at hand the pressure bandage provided by the employer.

Section 353 Felling Procedures

353.(1) Before starting to fell a tree, an employee shall ensure that

(a) all standing dead trees and other potential hazards are removed from the work area,

(b) there is a clear path of retreat to safety, and

(c) all other persons have moved at least 40 m from the felling area.

(2) Despite paragraph (1)(c), in a trail-cut operation, an employee shall ensure that, as soon as the tree begins to fall, any person assisting the employee moves at least 3 m away from the tree at a 45° angle from the direction opposite to the planned direction of fall.

[N.B. Reg. 2022-27, s. 56]

Section 353.1 Standing dead tree

353.1 (1) An employer and an employee shall, whenever possible, operate a powered mobile equipment to fell a standing dead tree.

(2) If a standing dead tree cannot be felled by operating a powered mobile equipment, an employee shall operate a chain saw to fell the standing dead tree and shall

(a) comply with sections 353 and 354 except for paragraph 354(2)(b),

(b) stand straight and tall to reduce the exposure of the employee’s neck and back, and

(c) use a lever instead of a wedge to avoid hitting the tree.

(3) If a standing dead tree cannot be felled by operating a powered mobile equipment or a chain saw, an employer shall

(a) develop written safe work procedures for hazardous operations caused by a standing dead tree that cannot be felled,

(b) ensure employees receive adequate instruction and training with respect to the safe work procedures for hazardous operations, and

(c) ensure that employees follow the safe work procedures for hazardous operations.

[N.B. Reg. 2022-27, s. 57]

Section 354

354. (1) In this section

"lodged tree" means a tree that has not fallen to the ground or a bed after being displaced from its natural position;

"spring pole" means a section of tree or bush which is, by virtue of its arrangement in relation to other materials, under compression.

(1.1) When felling a tree, an employee shall construct a hinge that will safely direct the tree to the ground by completing the following steps:

(a) cut an open face notch of at least 70° where the cut meets clean and even with no by-pass and make a back cut that is level and no more than 2.5 cm above the intersection of the two notch cuts;

(b) construct a uniform hinge that has a thickness of approximately 10% of the tree’s diameter and a width that is approximately 80% of the tree’s diameter; and

(c) follow the instructions referred to in paragraphs (a) and (b) as illustrated below:

(1.2) When felling a tree that is less than 10 cm in diameter, an employee shall construct a hinge by using the technique set out in subsection (1.1) or by completing the following steps:

(a) make a directional cut of at least 70°;

(b) make a back cut that is level and no more than 2.5 cm above the base of the directional cut;

(c) leave a hinge that has a thickness of approximately 10% of the tree’s diameter and a width that is approximately 80% of the tree’s diameter; and

(d) follow the instructions referred to in paragraphs (a) to (c) as illustrated below:

(2) When felling a tree, an employee shall

(a) Repealed. [N.B. Reg. 2022-27, s. 58]

(b) use a felling lever or wedge as required;

(c) complete the felling once it has been started; and

(d) subject to subsection (2.1), as soon as the tree begins to fall, move at least 3 m away from the tree at a 45° angle from the direction opposite to the planned direction of fall.

(2.1) When felling a tree on a slope greater than 30%, an employee may use an escape route that is perpendicular to the slope and not in the direction of the fall.

(3) Where an employee fells a tree and the tree becomes lodged, the employee shall

(a) stay in the area until the lodged tree is removed or if it is necessary to leave the area to obtain help to remove the tree, clearly mark as hazardous the area comprising a minimum radius of two tree lengths from the stump of the lodged tree

(b) ensure that the lodged tree is removed as soon as the circumstances permit by operating a powered mobile equipment without being climbed by any person, having another tree felled on it or having the supporting tree cut, and

(c) not do any work, other than removing the lodged tree, within the area referred to in paragraph (a).

(4) An employee shall not cut a spring pole in a manner that will endanger any person.

[N.B. Reg. 2001-33, s. 116; 2022-27, s. 58]

Section 355 Delimbing and Bucking

355. (1) When delimbing a fallen tree, an employee shall ensure that

(a) the tree to be delimbed is resting solidly on the ground,

(b) no person walks on the trunk of the tree while it is being delimbed, and

(c) whenever possible, the tree is worked on from the uphill side.

(2) When delimbing a fallen tree using a chain saw, an employee shall ensure that

(a) the tip of the chain saw guidebar is never used for delimbing,

(b) the chain saw is never positioned directly in front of the operator, and

(c) while delimbing or topping, the chain saw is never used with motions towards the employee.

Section 356

356. (1) In this section

"bucking" means cutting a tree into lengths after it has been felled and delimbed.

(2) When bucking a tree using a chain saw, an employee shall ensure that

(a) both feet are on the ground,

(b) the tree to be bucked is resting solidly on the ground, and

(c) the chain saw is never positioned directly in front of the employee.

Section 357 Safe Operation of Powered Mobile Equipment

357. (1) An employer shall ensure that

(a) subject to subsection (2), another employee is within 600 m of an employee operating powered mobile equipment, or

(b) the employee operating the powered mobile equipment is contacted at least every two hours and, if the employee exits the cab to perform work on the equipment, the employee contacts a person designated by the employer before exiting the cab.

(2) An employee other than the employee who is the operator of powered mobile equipment shall not work closer than 50 m from powered mobile equipment while the equipment is being operated, except when assisting an employee operating a skidder.

(3) An employee operating a skidder shall

(a) direct any person assisting the operator to stand clear of any trees or logs after the trees or logs have been attached to the skidder,

(b) not winch any trees or logs until the person assisting the operator is standing clear and opposite to the direction in which the load is to be winched and has signalled to the operator that the person is clear,

(c) operate the winch from the seat unless it is designed to be operated by remote control,

(d) keep the wheel chains on the skidder properly adjusted,

(e) lower the blade and apply the brakes when winching, and

(f) verify the location of the person assisting the operator before moving the skidder.

[N.B. Reg. 2022-27, s. 59]

Section 358 Hauling Logs

358. (1) An employer shall ensure that wire rope used for hauling logs is replaced when signs of wear or damage appear.

(2) Where wire rope is used for hauling logs, an employer shall ensure that cable cutters are readily available.

Section 359

359. When hauling logs with a wire rope, an employee shall attach the wire rope no farther than 1 m from the end of the log.

Section 359.1 Cable logging systems

359.1 Paragraphs 207(1)(a) and (b), sections 208, 209, 210 and 210.01, subsection 211(1), paragraphs 211(2)(a) to (f) and paragraphs 212(a), (b) and (d) apply, with the necessary modifications, to a cable logging system.

[N.B. Reg. 2022-27, s. 60]

Section 359.3 Remote control

359.3 (1) An employer shall ensure that a cable logging system is equipped with remote controls that have a fail-safe mechanism to prevent the simultaneous operation of two or more remote controls.

(2) An employer shall ensure that employees receive training on how to use the cable logging system.

[N.B. Reg. 2022-27, s. 60]

Section 360 Woods Roads

360. (1) In this section and sections 361 to 364, "woods road" means any road, other than a local government road or provincial highway, through a forest area that provides access for the harvesting and transportation of raw forest products by means of a vehicle.

(2) An employer shall ensure that a woods road

(a) is provided with wide sections for passing if the road has only one travelling lane,

(b) has stop signs conspicuously located at intersections,

(c) has signs warning of dangerous curves and blind or steep hills conspicuously located to allow for ample reaction time, and

(d) is kept in a safe condition.

(2.1) If a logging operation, a silviculture operation or woods road building work is being carried out and interferes with the flow of vehicular traffic, an employer shall ensure that adequate warning signs are posted and made visible in both directions.

(3) An employer shall ensure that a woods road is constructed as close as is practicable to a logging area to allow reasonable access and efficient evacuation in the event of an emergency.

(4) An employer or property owner shall notify the authority owning or operating an energized electrical utility line of the intention to build a woods road close to the electrical utility line, the location of the planned work and the time and duration of the planned work before any work is done.

(5) An employer shall ensure that a woods road is not built any closer to an energized electrical utility line than the distances specified by an authority referred to in subsection (4).

[N.B. Reg. 2005-80, s. 2; S.N.B. 2017, c. 20, s. 122; 2022-27, s. 61]

Section 361

361. (1) An employer shall ensure that a bridge on a woods road

(a) is constructed according to a plan approved by an engineer,

(b) has the load capacity conspicuously posted 30 m from both ends of the bridge, and

(c) has a warning sign conspicuously located 90 m from the bridge if the bridge is not visible from that distance.

(2) An employer shall ensure that a bridge or culvert on a woods road

(a) that is over 1.2 m in height has bumpers at least 250 mm high running the length of the bridge or culvert on both sides,

(b) has a hazard marker located on each corner of the bridge or culvert with the bottom of the marker not less than 1.5 m or more than 2.5 m above the level of the travelled portion of the road, and

(c) has a sign conspicuously located along the side of the road at least 150 m from the bridge or culvert warning of a narrow passage if the width of the bridge or culvert is less than that of the woods road.

Section 362

362. An employer shall ensure that a sign or hazard marker used on a woods road is constructed of light reflective material and is of suitable dimensions so as to be clearly visible under normal driving conditions.

Section 363

363. An operator of a vehicle shall keep the headlights of the vehicle on while driving on a woods road.

Section 363.1 Driving conditions on woods roads

363.1 An operator of a vehicle driving on a woods road shall do so with due regard to the traffic, the environmental conditions and the condition of the woods road and, if applicable, the speed limit set by the owner of the woods road.

[N.B. Reg. 2022-27, s. 62]

Section 364 Loading Operations

364 (1) An employer and an employee shall ensure that a truck load of logs travelling on a woods road is secure by complying with the requirements set out in this section.

(2) The truck shall be equipped on the top and on the rear of the cab with structural protection that is strong enough to restrain the cargo.

(3) A rear overhang exceeding 1 m shall have a visible means of identification.

(4) A stack of wood in the load shall be restrained with a minimum of two tie-downs.

(5) Stakes that are not permanently attached to the truck frame or bunk shall be secured in a manner that prevents the stakes from separating from the truck while it is travelling on a woods road.

(6) The weight of the load shall not create a hazard.

(7) An employer shall ensure that an employee conducts a walk around inspection of the load at checkpoints that are designated by the employer and marked with signs along the woods road and before

(a) leaving the work area,

(b) entering a highway, and

(c) removing load binders at an off-loading site.

[N.B. Reg. 2022-27, s. 63]