WHMIS

WHMIS stands for the Workplace Hazardous Materials Information System. It is a system for providing health and safety information on the safe use of hazardous products in Canadian workplaces. The main components of WHMIS are hazard identification and product classification, labelling, safety data sheets, employee education, instruction and training, and the protection of confidential business information.

Effective April 1, 2016, the Workplace Hazardous Materials Information System Regulation - Occupational Health and Safety Act has been amended to align with the amended Hazardous Products Act (HPA) and Hazardous Products Regulations (HPR), which incorporate the GHS. It is now referenced as WHMIS Regulation 2016-6.

Suppliers must:

- Ensure the appropriate classification of hazardous products.

- Provide labels.

- Provide Safety Data Sheets (SDSs).

Employers must:

- Educate, instruct and train employees on the hazards and safe use of products.

- Ensure that hazardous products are properly labelled.

- Prepare workplace labels and SDSs as necessary.

- Provide employees with access to up-to-date SDSs.

- Review the education, instruction and training provided to employees – annually or whenever work conditions or hazard information changes.

Periodically, assess employee knowledge of WHMIS.

Employees must:

- Participate in WHMIS education, instruction and training programs.

- Take necessary steps to protect themselves and their co-workers.

- Participate in identifying and controlling hazards.

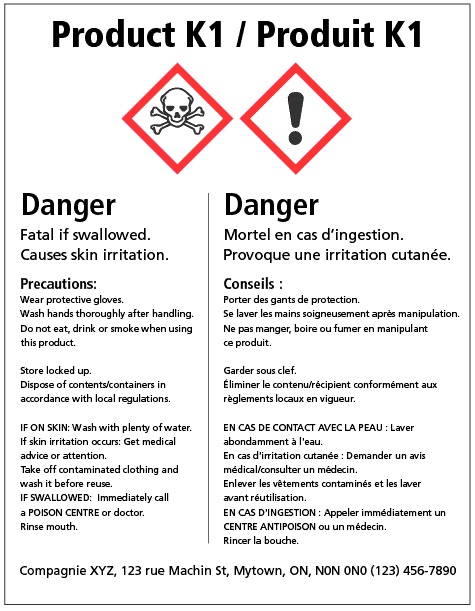

WHMIS legislation requires that products used in the workplace that meet the criteria of “hazardous products” must be labelled. In most cases, suppliers are responsible for labelling the hazardous products that they provide to customers. Employers must ensure that hazardous products that come into the workplace are labelled. They are also responsible to prepare and apply a workplace label, when appropriate.

Supplier labels must be available in English and French. They may be bilingual (as one label), or available as two labels (one each in English and French).

Under WHMIS, variations on the supplier label apply for specific situations such as:

- Bulk shipments – A labelling exemption exists for products sold without packaging.

- 100 mL or less – Exempt only from requirement to have precautionary or hazard statements on the label.

- 3 mL or less – Where the label will interfere with normal product use, the product must have a label that is durable and legible for transport and storage, but may be removed during use.

Sample Supplier Label for WHMIS

Workplace Labels

A workplace label is required when:

- A hazardous product is produced (made) at the workplace and used in that workplace.

- A hazardous product is decanted into another container.

- A supplier label becomes lost or illegible (unreadable).

There are two situations when a workplace label is not necessary. When a hazardous product is:

- Decanted into a container and it is going to be used immediately.

- “Under the control of the person who decanted it". For example, when the person who poured the product into another container will be the only person who will use it, and the product will be used during one shift, a full workplace label may not be required. However, the container must still be identified with the product identifier (name).

If the product is not used right away, or if more than one person will be in control of the product, a full workplace label is required.

In New Brunswick, a WHMIS workplace label will require the following information:

- Product identifier.

- Hazard pictograms (optional).

- Precautionary statements.

- A reference to the SDS (if available).

Other situations where alternative labels may be used include:

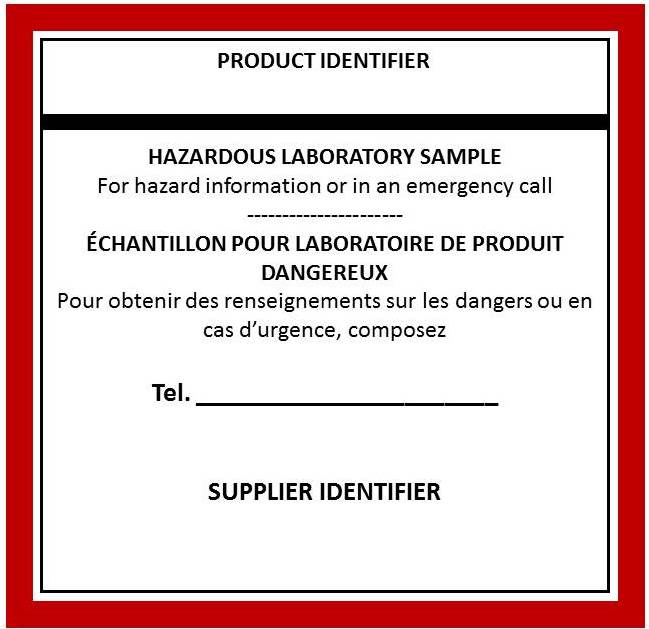

- Laboratory samples –

- Under WHMIS laboratory samples are exempt from requiring a label as long as the following is present:

- The chemical name or generic chemical name, if known.

- The statement “Hazardous Laboratory Sample. For hazard information or in an emergency, call / Échantillon pour laboratoire de produit dangereux. Pour obtenir des renseignements sur les dangers ou en cas d’urgence, composez” and an emergency telephone number.

- Under WHMIS laboratory samples are exempt from requiring a label as long as the following is present:

Sample Laboratory Label for WHMIS

Safety Data Sheets (SDSs) are documents that provide information about a product's hazards and safety precautions. SDSs are usually written by the product's manufacturer or supplier. In some circumstances, an employer may be required to prepare an SDS (for example, when the product is produced and used exclusively in that workplace). Every product that is classified as a “hazardous product” under WHMIS that is intended for use, handling or storage in a workplace in Canada must have an SDS.

In WHMIS, every SDS must provide a date of last revision in Section 16 – Other Information. SDSs are required to be accurate at the time of sale. An SDS will be required to be updated when the supplier becomes aware of any significant new data (SDS must be updated when there is new information that changes how the hazardous product is classified, or when there are changes to the way you will handle or store or protect yourself from the product's hazards). Note that there is no requirement for the supplier to provide an updated SDS to past purchasers of a hazardous product.

In WHMIS, an employer must ensure that the SDSs in their workplace are the most current ones available.

Education, Instruction and Training

Employees must be educated, instructed and trained so they understand the hazards, and know how to work safely with hazardous products. Education, instruction and training can be thought of as three separate parts.

- Education refers to general or portable information such as how WHMIS works and the hazards of the products. For example, you will learn about the hazard classes (for example, why a product is called a corrosive, and what information you can find on labels and SDSs).

- Instruction refers to the detailed information provided to an employee, either verbally or in writing, about how something should be done.

- Training refers to the site- and job-specific information that covers your workplace's procedures for storage, handling, use, disposal, emergencies, spills, and what to do in unusual situations.

As an employer you must establish a program of employee education, instruction and training for your workplace that:

- Is developed and implemented in consultation with the committee or health and safety representative, if any, for the place of employment.

- Relates to any other hazard prevention and control program in place.

- Results in employees being able to apply the information to protect their health and safety.

- Periodically evaluates employee knowledge of WHMIS using written tests, practical demonstrations or other appropriate means.

- Is reviewed at least once a year, in consultation with the committee or health and safety representative, if any, to determine if any change in work conditions or available hazard information requires a change in the program of employee education, instruction and training.

Employers and employees must ensure that they can answer these questions for every hazardous product they work with:

- What are the product's hazards?

- How do I protect myself from those hazards?

- What do I do in an emergency?

- Where can I get more information?

What is the standard for employee WHMIS education, instruction, training and evaluation?

An education, instruction and training program is considered effective when employees can apply the information they were taught to protect their own health and safety.

To determine if this standard has been met, an employer could offer practical or written tests or assess employees through job observation. The law does not specify how to conduct education, instruction and training, how frequently it must be conducted or how to test for its effectiveness. Ways to implement education, instruction and training and test for results is left to the employer to determine. However, an employee can expect to undergo a written test as part of the generic WHMIS education evaluation. Job observations and demonstrations are also valid and often part of a site-specific training evaluation.

Many private consultants provide training services to help employers develop or present generic WHMIS employee education. Employers can also prepare and deliver their own courses, as long as all the necessary information is covered.

Worksite-specific training –Worksite-specific training includes training on the procedures (operations and emergency) established by the employer or organization, specifically related to the hazardous product(s), process or task being used or carried out. While training can be provided by an outside company, to be effective, the firm would have to be familiar with the processes and all the hazardous products used at that workplace. Therefore, this training is best designed and provided by onsite personnel.

In summary, the legislation places the obligation for education, instruction and training with the employer, and it outlines the minimum requirements. This may be provided by the employer, or by a qualified person or agency that the employer has chosen. Regardless of who delivers the education, instruction and training, employers remain legally responsible to ensure that any education, instruction and training results in the protection of employees.

Confidential Business Information

A supplier can apply to have the hazardous product's exact ingredients and/or their concentration considered as "confidential business information" (CBI). A strict process must be followed to have an ingredient or ingredients considered as confidential business information, and approval is only granted by Health Canada. For example, a CBI claim may be granted if stating the ingredient name on the SDS would give competitors financial gain and/or there was a significant cost to the product development.

Each claim is given a Registry Number. The Registry Number and approval or filing date must be shown on the SDS. If the name of an ingredient is claimed as CBI, a generic chemical identity must be listed, as well as all physical or health hazard information, preventive measures and first aid.

While the ingredients may not be disclosed on the SDS, the supplier is required to disclose the ingredient's name to a safety or health professional for example, in an emergency.

Employers who produce hazardous products for their workplace and/or for commercial sales and applications have the same legal rights as suppliers to protect information that believe may affect their business. The process to follow is similar to those required by suppliers. Also, where required, employers must also disclose the CBI to a medical practitioner (doctor) or nurse.

“supplier” means a person who, in the course of business, sells or imports a hazardous product

This responsibility is to ensure that employees are always adequately educated, instructed and trained. Knowledge of the employees may be evaluated by using written tests, practical demonstration or other suitable means. How to assess employees' knowledge and the how often shall be determined by the employer in consultation with the committee or health and safety rep, in any.

“bulk shipment” means a shipment of a hazardous product that is contained in any of the following, without intermediate containment or intermediate packaging:

(a) a vessel that has a water capacity equal to or greater than 450 litres;

(b) a freight container, road vehicle, railway vehicle or portable tank;

(c) the hold of a ship; or

(d) a pipeline.

Section 5.4 Small-capacity containers – 100 ml or less

5.4. (1) The sale or importation of a hazardous product in a container that has a capacity of less than or equal to 100 ml, including any subsequent container of the same capacity in which that first container is packaged, is exempt from the application of paragraph 3(1)(c) and subparagraph 3(1)(d)(i) or (ii) in respect of the requirement to provide any precautionary statement or hazard statement on the label of the hazardous product or the container.

From the Canada Hazardous Products Regulations SOR/2015-17

“workplace label”, with respect to a hazardous product, means a label provided by an employer which discloses

(a) a product identifier which is identical to that found on the safety data sheet of the corresponding hazardous product,

(b) information for the safe handling of the hazardous product which is conveyed in a manner appropriate to the workplace, and

(c) that a safety data sheet, if supplied or produced, is available.

For example, transferred or poured.

For example, transferred or poured.

The product name exactly as it appears on the container and on the Safety Data Sheet (SDS).

Hazard pictograms are determined by the hazard classification of the product. Hazard statements based on the product’s hazard classification may also be included.

These standardized statements describe recommended measures to minimize or prevent adverse effects from exposure to the product, including protective equipment and emergency measures. First aid is included in precautionary statements. Pictograms describing control measures can also be used.

“laboratory samples” means a sample of a hazardous product that is packaged in a container that contains less than 10 kg of the hazardous product and that is intended solely to be tested in a laboratory, but does not include a sample that is to be used

(a) by the laboratory for testing other products, materials or substances, or

(b) for educational or demonstration purposes.

“safety data sheet” includes an employer safety data sheet and a supplier safety data sheet

“significant new data” means new data regarding the hazard presented by a hazardous product that changes its classification in a category or subcategory of a hazard class, or results in its classification in another hazard class, or change the ways to protect against the hazard presented by the hazardous product

“education” means the delivery of general or portable information to employees

“instruction” means detailed information provided either verbally or in writing to an employee describing how something should be done, operated or assembled

“training” means the delivery of worksite and job-specific information to employees

“One way to do this is to take a product used at the workplace and go over the information found on the label and its meaning, the content of the SDS focusing on required protective measures (i.e. PPE), emergency response such as first aid and what to do in the event of a spill.”

Workplace Hazardous Materials Information System Regulation - Occupational Health

and Safety Act

N.B. Reg. 2016-6

EMPLOYEE EDUCATION, INSTRUCTION AND TRAINING

Section 7 Program of employee education, instruction and training

7. (1) An employer shall ensure that an employee who works with a hazardous product or who may be exposed to a hazardous product in the course of his or her work activities receives education, instruction and training in

(a) the content required on a supplier label and workplace label and the purpose and significance of the information contained on the labels,

(b) the content required on a safety data sheet and the purpose and significance of the information contained on the safety data sheet,

(c) procedures for the safe use, storage, handling and disposal of a hazardous product,

(d) specific information needed for the safe use, storage, handling and disposal of a hazardous product contained or transferred in

(i) a pipe,

(ii) a piping system including valves,

(iii) a process vessel,

(iv) a reaction vessel, or

(v) a tank car, tank truck, ore car, conveyor belt or similar conveyance,

(e) procedures to be followed where fugitive emissions are present and where employees may be exposed to the fugitive emissions, and

(f) procedures to be followed in case of an emergency involving a hazardous product.

(2) An employer shall ensure that the program of employee education, instruction and training required by subsection (1) is

(a) developed and implemented for the employer’s place of employment,

(b) related to any other hazard prevention and control program at the place of employment, and

(c) developed and implemented in consultation with the committee, if any, or the health and safety representative, if any.

(3) So far as is reasonably practicable, an employer shall ensure that

(a) the program of employee education, instruction and training required by subsection (1) results in an employee being able to apply the information as needed to protect the employee’s health and safety,

(b) the knowledge of the employees is periodically evaluated using a written test, practical demonstration or other suitable means, and

(c) the requirements of paragraph (b) are determined in consultation with the committee, if any, or the health and safety representative, if any.

(4) An employer shall review at least annually, or more frequently if required by a change in work conditions or available hazard information, and in consultation with the committee, if any, or health and safety representative, if any, the education, instruction and training provided to employees concerning hazardous products.

LABELLING AND IDENTIFICATION

Section 8 Supplier labels

8. (1) Subject to any exemptions with respect to labelling requirements under the Hazardous Products Regulations , an employer shall ensure that a hazardous product or the container of a hazardous product that is received at a place of employment has a label that complies with the requirements set out in those regulations affixed to it, printed on it or attached to it or to the container in which it was packaged in a manner that complies with the requirements set out in those regulations.

(2) If, pursuant to an exemption under section 5.15 of the Hazardous Products Regulations , a hazardous product is imported and received at a place of employment without a supplier label, or with a supplier label that does not comply with the requirements of the Hazardous Products Regulations, an employer

(a) if the product is to be used solely in the workplace, shall affix a workplace label that meets the requirements of this Regulation, and

(b) if the product is intended to be resold, shall affix a label that meets the requirements of the Hazardous Products Regulations .

(3) An employer who receives an unpackaged hazardous product or a hazardous product transported as a bulk shipment at a place of employment to which, pursuant to an exemption under subsection 5.5(2) of the Hazardous Products Regulations , a supplier label has not been affixed or attached, shall affix a label having the information required of a supplier label to the container of the hazardous product or to the hazardous product.

(4) Subject to an exemption with respect to labelling requirements under the Hazardous Products Regulations , and subject to section 17, if any amount of a hazardous product remains in a place of employment in the container in which it was received from the supplier, an employer shall not remove, deface, modify or alter the supplier label, with the exception of the removal of the label under normal conditions of use of a hazardous product in a container that has a capacity of 3 ml or less where the label interferes with the normal use of the product.

(5) An employer shall update the labels or the information on containers as soon as significant new data is provided to the employer from the supplier.

(6) If a label applied to a hazardous product or a container of a hazardous product becomes illegible or is accidentally removed, other than the removal of a label where the container of the hazardous product has a capacity of 3 ml or less under normal conditions of use and the label interferes with the normal use of the product, the employer shall replace the label with either a supplier label or a workplace label.

Section 9 Workplace labels

9. (1) If an employer produces a hazardous product, other than a fugitive emission, the employer shall ensure that the hazardous product or the container of the hazardous product has a workplace label applied to it.

(2) An employer shall update the workplace labels as soon as significant new data is available to the employer.

(3) Subsection (1) does not apply if the hazardous product is in a container that is intended to contain the hazardous product for sale or disposition and the container is or is about to be appropriately labelled.

Section 10 Workplace label for decanted products

10. (1) If a hazardous product is in a container that is not the container in which it was received from the supplier, an employer shall ensure that the container is labelled with a workplace label.

(2) Subsection (1) does not apply in respect of a portable container that has been filled directly from a container with a supplier label or workplace label if

(a) the hazardous product

(i) is under the control of and is used exclusively by the employee who filled the portable container,

(ii) is used only during the shift in which the portable container is filled, and

(iii) in the portable container is clearly identified, or

(b) all of the hazardous product in the portable container is required for immediate use.

Section 11 Identification of a hazardous product in piping systems and vessels

11. An employer shall ensure the safe use, storage and handling of a hazardous product through employee education, instruction and training and the use of colour coding, labels, placards or any other mode of identification if the hazardous product is contained or transferred in any of the following:

(a) a pipe;

(b) a piping system including valves;

(c) a process vessel;

(d) a reaction vessel; or

(e) a tank car, tank truck, ore car, conveyor belt or similar conveyance.

Section 13 Laboratory labels

13. (1) If a laboratory sample of a hazardous product is the subject of a labelling exemption under subsection 5(5) or (6) of the Hazardous Products Regulations , a label provided by the supplier and affixed to, printed on or attached to the container of the product received at the place of employment that discloses the following information in place of the information required under paragraphs 3(1)(c) or (d) of the Hazardous Products Regulations complies with the requirements of section 8 with respect to a supplier label:

(a) the chemical name or generic chemical name of any material or substance in the hazardous product that, individually, is classified pursuant to the Hazardous Products Act and the Hazardous Products Regulations in any category or subcategory of a health hazard class and is present above the relevant concentration limit, or is present at a concentration that results in the mixture being classified in a category or subcategory of any health hazard class, if known by the supplier; and

(b) the statement "Hazardous Laboratory Sample. For hazard information or in an emergency, call / Échantillon pour laboratoire de produit dangereux. Pour obtenir des renseignements sur les dangers ou en cas d’urgence, composez" followed by an emergency telephone number for the purpose of obtaining the information that must be provided on the safety data sheet of the hazardous product.

(2) If a hazardous product is in a container, other than the container in which it was received from a supplier, or is produced in the place of employment, the employer is exempt from the requirement of section 10 if the hazardous product

(a) is a laboratory sample;

(b) is intended by the employer solely for use, analysis, testing or evaluation in a laboratory, and

(c) is clearly identified through a combination of

(i) a mode of identification visible to employees at the place of employment, and

(ii) employee education, instruction and training required by this Regulation.

(3) The employer shall ensure that the mode of identification and employee education, instruction and training used under subsection (2) enables the employees to readily identify and obtain either the information required on a safety data sheet, if one has been produced, or a label or document disclosing the information referred to in paragraphs (1)(a) and (b) with respect to the hazardous product or the sample.

(4) If a hazardous product is produced in a laboratory, the employer is exempt from the requirements of sections 9 and 10 if the hazardous product

(a) is intended by the employer solely for evaluation, analysis or testing for research and development,

(b) is not removed from the laboratory, and

(c) is clearly identified through a combination of

(i) any mode of identification visible to employees at the place of employment, and

(ii) employee education, instruction and training required by this Regulation.

(5) The employer shall ensure that the mode of identification and employee education, instruction and training used under subsection (4) enables employees to readily identify and obtain either the information required on a safety data sheet, if one has been produced, or any other information that is necessary to ensure the safe use, storage and handling of the hazardous product.

SAFETY DATA SHEETS

Section 14 Supplier safety data sheets

14. (1) Subject to subsection (2), an employer who acquires a hazardous product for use, handling or storage at a place of employment shall obtain a supplier safety data sheet in respect of that hazardous product that complies with the requirements of the Hazardous Products Regulations .

(2) If a supplier is exempted by the Hazardous Products Regulations from the requirement to provide a safety data sheet for a hazardous product, the employer is exempt from the requirement to obtain and provide a safety data sheet for that hazardous product.

(3) If an employer is unable to obtain an up-to-date supplier safety data sheet referred to in subsection (1), the employer shall add any significant new data applicable to the hazardous product to the most recent supplier safety data sheet obtained under that subsection on the basis of the ingredients of the hazardous product disclosed in that supplier safety data sheet.

(4) An employer may provide a safety data sheet in a format different from the format in the supplier safety data sheet or containing additional hazard information if

(a) it discloses no less information than that disclosed on the supplier safety data sheet,

(b) it indicates that the supplier safety data sheet is available, and

(c) the employer makes the supplier safety data sheet readily available.

(5) If a hazardous product is received at a laboratory from a laboratory supply house or is a laboratory sample and the supplier has provided a safety data sheet, an employer shall ensure that a copy of the safety data sheet is made available to employees in the laboratory.

Section 15 Employer safety data sheets

15. (1) If an employer produces a hazardous product in the workplace, the employer shall prepare a safety data sheet in respect of that product which discloses, subject to section 17 of this Regulation and Part 5 of the Hazardous Products Regulations , the information required under the Hazardous Products Regulations.

(2) For purposes of subsection (1), "produces" does not include the production of a fugitive emission or intermediate products undergoing reaction within a reaction or process vessel.

(3) If a hazardous product is received or produced at a laboratory and the employer has prepared a safety data sheet, the employer shall ensure that the safety data sheet is made available to employees in the laboratory.

(4) An employer shall disclose the source of any toxicological data used in preparing an employer safety data sheet to

(a) an employee on request,

(b) an officer on request, and

(c) a member of the committee, if any, or to a health and safety representative, if any, on request.

(5) An employer shall update an employer safety data sheet as soon as practical and not later than 90 days after significant new data becomes available to the employer.

Section 16 Availability of safety data sheets

16. An employer shall ensure that

(a) a copy of a safety data sheet referred to in sections 14 and 15 is readily available to employees who may be exposed to the hazardous product and to the committee, if any, or to a health and safety representative, if any, and

(b) the committee, if any, or a health and safety representative, if any, is consulted on the means to best achieve safety data sheet accessibility in the place of employment.

CLAIMS FOR EXEMPTION

Section 18 Procedure

18. (1) Any employer who is required to disclose any of the following information on a label or safety data sheet may claim, if the employer considers it to be confidential business information, an exemption from the requirement to disclose that information

(a) in the case of a material or substance that is a hazardous product,

(i) the chemical name of the material or substance,

(ii) the CAS registry number or any other unique identifier of the material or substance, and

(iii) the chemical name of any impurity, stabilizing solvent or stabilizing additive that is present in the material or substance that is classified in a category or subcategory of a health hazard class under the Hazardous Products Act and that contributes to the classification of the material or substance in the health hazard class under that Act;

(b) in the case of an ingredient that is in a mixture that is a hazardous product,

(i) the chemical name of the ingredient,

(ii) the CAS registry number or any other unique identifier of the ingredient, and

(iii) the concentration or concentration range of the ingredient;

(c) in the case of a material, substance or mixture that is a hazardous product, the name of any toxicological study that identifies the material or substance or any ingredient in the mixture;

(d) the product identifier of a hazardous product, being its chemical name, common name, generic name, trade-name or brand name;

(e) information about a hazardous product, other than the product identifier, that constitutes a means of identification; and

(f) information that could be used to identify a supplier of a hazardous product.

(2) The Minister of Health (Canada) is designated for the purpose of determining if a claim for an exemption from the requirement to disclose the information considered by the employer to be confidential business information is valid.

(3) A claim under subsection (1) shall be filed in accordance with the procedures for a claim established under the Hazardous Materials Information Review Act .

18(4) The Minister of Health (Canada) shall, with the necessary modifications, exercise the powers, perform the functions and follow the procedures under the Hazardous Materials Information Review Act and the regulations under that Act in respect of a claim made under subsection (1).

(5) Information that an employer considers to be confidential business information is exempt from disclosure from the time a claim is filed under subsection (1) until the final disposition of the proceedings in relation to the claim and, if the claim is found to be valid, for a period of three years from the date that the claim is determined.

(6) An employer who makes a claim under subsection (1) shall abide by orders and decisions issued under the Hazardous Materials Information Review Act and the regulations under that Act.

(7) An appeal of an order or decision referred to in subsection (6) shall be made in the same manner, with the necessary modifications, as an appeal under the Hazardous Materials Information Review Act and the regulations under that Act.